减速机技术参数请咨询江苏泰工减速机有限公司,【紧急发货请联系客服,15052132938(同微信),13861467735(同微信)400-710-9918】

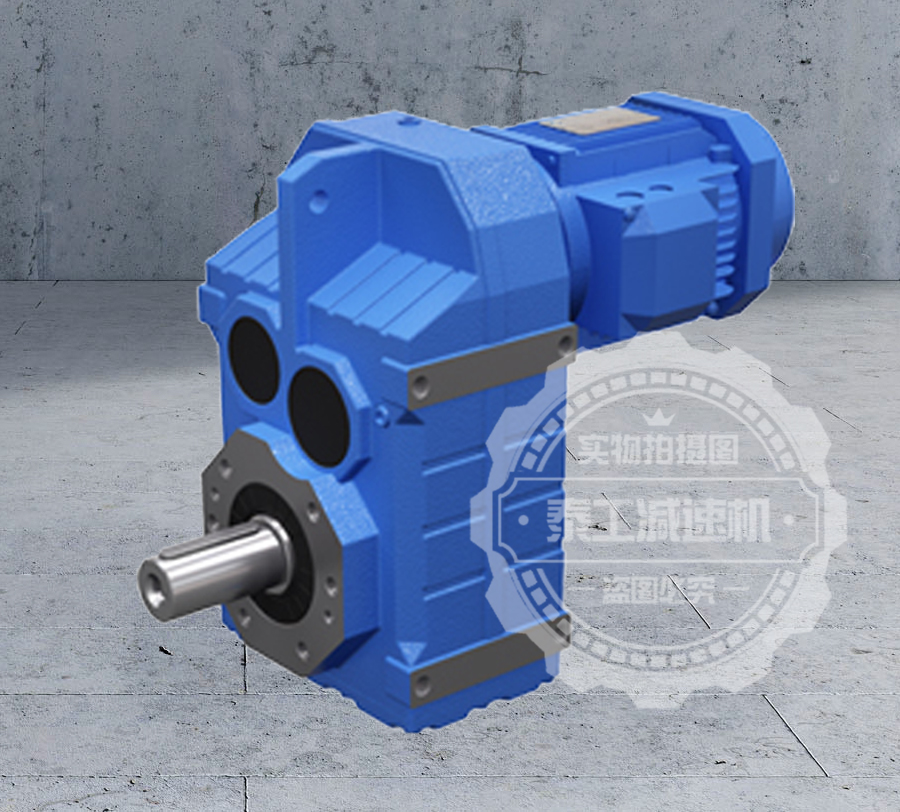

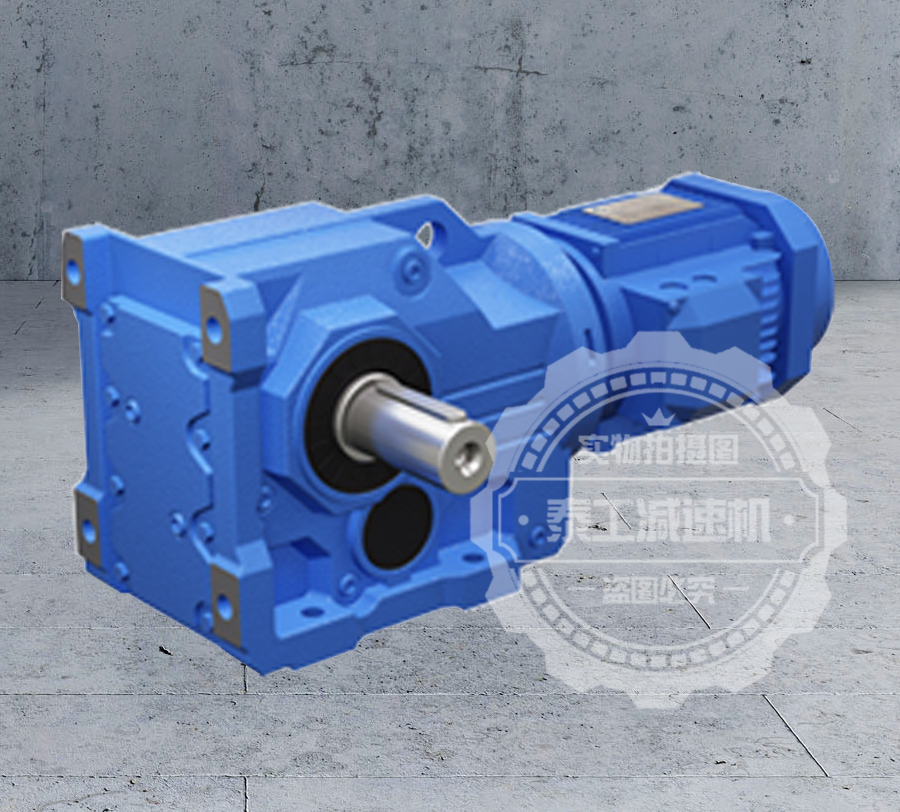

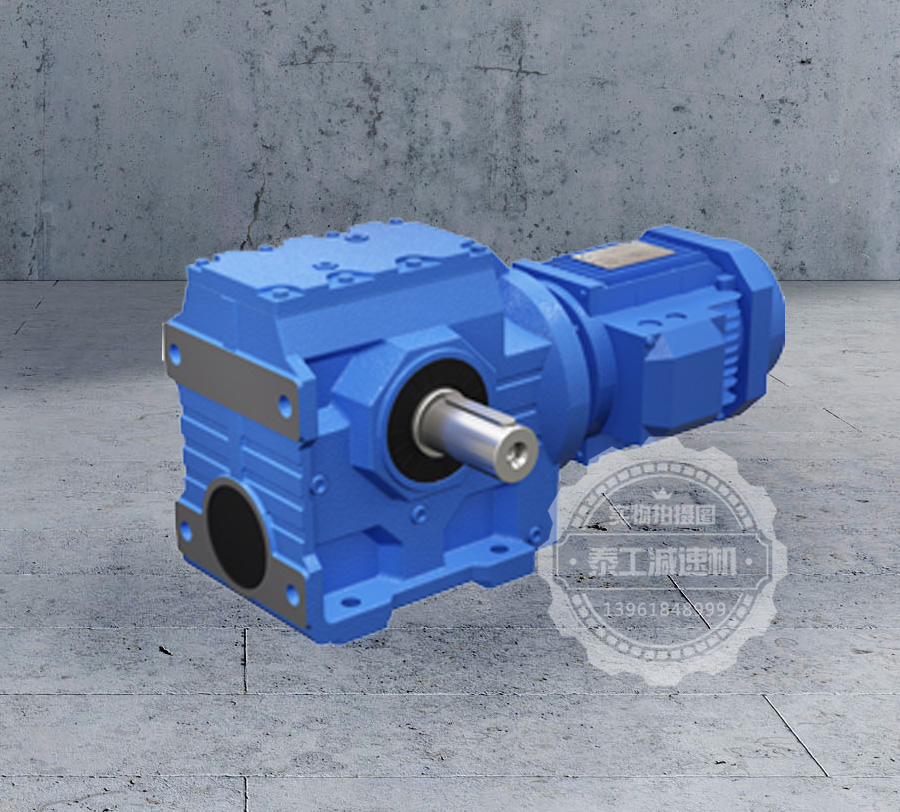

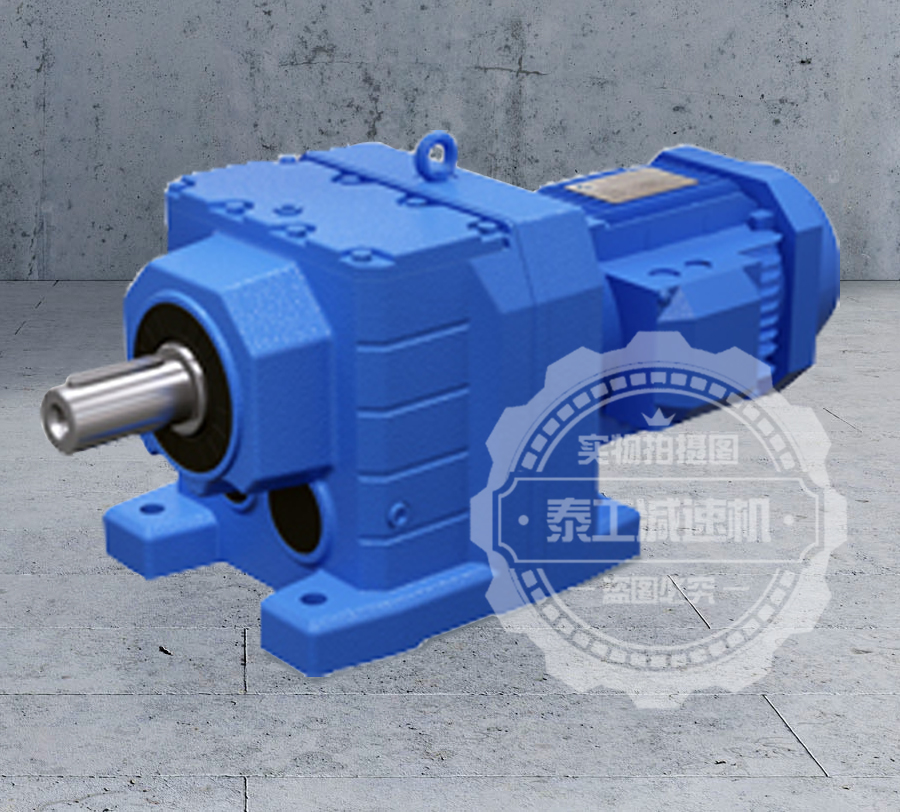

泰工减速电机具有效率及可靠性高,工作寿命长,维护简便等诸多优点。泰工减速机专业生产减速电机,摆线针轮减速机,行星减速机,电动滚筒,齿轮减速机,硬齿面减速机,摆线减速机,蜗轮减速机,伺服减速机等。

TCS型垂直轴轴装减速器适用范围及标记方法

一、概述

TCS是TC的变型产品,同样适用于起重、运输、冶金、矿山,石油化工、建筑等行业的传动机构。

二、型号、装配型式及表示方法

1.型号:10、12、16、20、25

2.标记方法:

机座号

|

L

|

K

|

H

|

C

|

U

|

W

|

V

|

a

|

a1

|

n

|

q

|

r

|

d

|

b

|

D1

|

D2

|

D3

|

S

|

重量Kg

|

TCS10

|

208

|

274

|

490

|

104

|

137

|

40

|

125

|

225

|

325

|

127

|

86

|

56

|

22

|

26

|

132

|

152

|

172

|

M12

|

75

|

TCS12

|

255

|

346

|

612

|

127.5

|

173

|

45

|

150

|

280

|

406

|

160

|

101.5

|

70

|

26

|

36

|

160

|

180

|

203

|

M16

|

142

|

TCS16

|

264

|

400

|

760

|

132

|

200

|

55

|

180

|

355

|

485

|

220

|

104

|

85

|

34

|

46

|

160

|

180

|

208

|

M16

|

210

|

TCS20

|

318

|

500

|

930

|

159

|

250

|

55

|

220

|

470

|

625

|

250

|

140

|

100

|

40

|

50

|

210

|

180

|

280

|

M16

|

350

|

TCS25

|

356.5

|

620

|

1160

|

178.25

|

350

|

75

|

275

|

580

|

777

|

310

|

180

|

125

|

40

|

70

|

240

|

240

|

320

|

M20

|

820

|

机座代号

|

花键

|

平键

|

|||||||||

花键副

|

内花键大径D

|

外花键大径d

|

k2

|

t

|

S1

|

d1

|

d2

|

d3

|

b3

|

t3

|

|

10

|

INT/EXT31Z×2m×30p×6H/6h

|

65

|

64

|

208

|

60

|

2

|

57

|

60

|

50

|

14

|

53.8

|

12

|

INT/EXT35Z×3m×30p×6H/6h

|

85.5

|

84

|

255

|

65

|

2.5

|

75

|

78

|

60

|

18

|

64.4

|

16

|

INT/EXT35Z×3m×30p×6H/6h

|

109.5

|

108

|

264

|

75

|

2.5

|

96.5

|

100

|

90

|

25

|

95.4

|

20

|

318

|

85

|

2.5

|

96.5

|

100

|

100

|

28

|

106.4

|

|||

25

|

356.5

|

95

|

2.5

|

96.5

|

100

|

100

|

28

|

106.4

|

|||

承载能力:

2.工作级别为M5时,减速器承载能力表

| 公称传动比i | 公称传速r/min | 规格 | |||||

| 输入n1 | 输出n2 | 10 | 12 | 16 | 20 | 25 | |

| 公称输入功率 P KW | |||||||

| 22.4 | 1500 | 66 | 9.1 | 22.8 | 38.9 | 81 | 96 |

| 1000 | 44 | 6.1 | 15.2 | 25.9 | 54 | 64 | |

| 750 | 33 | 4.50 | 11.4 | 19.5 | 40 | 48 | |

| 25 | 1500 | 60 | 8.3 | 21.5 | 35 | 70 | 89 |

| 1000 | 40 | 5.5 | 16.5 | 23.3 | 46.5 | 59 | |

| 750 | 30 | 4.1 | 11 | 17.5 | 35 | 44.5 | |

| 28 | 1500 | 53.5 | 7.8 | 19.2 | 30.3 | 67 | 82 |

| 1000 | 35.5 | 5.2 | 12.5 | 20 | 44.5 | 54.5 | |

| 750 | 26.5 | 3.9 | 9.6 | 15.2 | 33.5 | 41 | |

| 31.5 | 1500 | 47.5 | 7.8 | 17.9 | 27.4 | 60 | 75 |

| 1000 | 31.5 | 5.2 | 11.9 | 18.2 | 40 | 50 | |

| 750 | 23.5 | 3.9 | 9 | 13.7 | 30 | 37 | |

| 35.5 | 1500 | 42 | 6.9 | 15.2 | 25.8 | 50 | 70 |

| 1000 | 28 | 4.6 | 10.1 | 17.2 | 33 | 46 | |

| 750 | 21 | 3.5 | 7.6 | 12.9 | 25 | 35 | |

| 40 | 1500 | 37.5 | 6.2 | 13.5 | 23 | 40 | 60 |

| 1000 | 25 | 4.1 | 9 | 15 | 26.5 | 40 | |

| 750 | 18.3 | 3.1 | 6.7 | 11.5 | 20 | 30 | |

| 45 | 1500 | 33 | 5.3 | 12.0 | 19.5 | 37 | 54 |

| 1000 | 22 | 3.5 | 8 | 13 | 24.5 | 36 | |

| 750 | 16.5 | 2.7 | 6 | 10 | 18.5 | 27 | |

| 50 | 1500 | 30 | 5.1 | 10.8 | 19.5 | 35 | 51 |

| 1000 | 20 | 3.4 | 7.2 | 13 | 23 | 34 | |

| 750 | 15 | 2.5 | 5.4 | 10 | 17.5 | 25.5 | |

| 56 | 1500 | 26.5 | 4.3 | 9.4 | 16.3 | 27 | 45 |

| 1000 | 17.5 | 2.8 | 6.2 | 10.8 | 18 | 30 | |

| 750 | 13 | 2.2 | 4.7 | 8.2 | 13.5 | 22.5 | |

| 63 | 1500 | 23.5 | 3.9 | 8.4 | 15.1 | 25 | 43 |

| 1000 | 15.5 | 2.6 | 5.6 | 10 | 16.5 | 28.5 | |

| 750 | 12 | 2 | 4.2 | 7.5 | 12.5 | 21.5 | |

| 71 | 1500 | 21 | 3.6 | 7.0 | 13 | 22 | 38 |

| 1000 | 14 | 2.4 | 4.5 | 8.5 | 15 | 25 | |

| 750 | 10.5 | 1.8 | 3.5 | 6.5 | 11 | 19 | |

| 80 | 1500 | 18.5 | 3.0 | 6.7 | 11 | 17 | 35 |

| 1000 | 12.5 | 2 | 4.5 | 7.3 | 11 | 23 | |

| 750 | 9 | 1.5 | 3.3 | 5.5 | 8.5 | 17.5 | |

| 90 | 1500 | 16.5 | 2.8 | 5.6 | 9.2 | 16 | 28 |

| 1000 | 11 | 1.8 | 3.7 | 6.1 | 10.5 | 18.5 | |

| 750 | 8 | 1.4 | 2.8 | 4.6 | 8 | 14 | |

| 100 | 1500 | 15 | 2.5 | 5.2 | 8.6 | 13 | 25 |

| 1000 | 10 | 1.6 | 3.4 | 5.7 | 8.6 | 16.5 | |

| 750 | 7.5 | 1.3 | 2.6 | 4.3 | 6.5 | 12.5 | |

| 115 | 1500 | 13 | 2.3 | 5 | 8.1 | 12 | 23 |

| 1000 | 8.5 | 1.5 | 3.3 | 5.4 | 8 | 1.5 | |

| 750 | 6.5 | 1.2 | 2.5 | 4.1 | 6 | 11.5 | |

| 128 | 1500 | 11.5 | 1.8 | 4.2 | 6.8 | 10.5 | 21 |

| 1000 | 7.5 | 1.2 | 2.8 | 4.5 | 7 | 14 | |

| 750 | 5.5 | 0.9 | 2.1 | 3.4 | 5.3 | 11 | |

| 145 | 1500 | 10 | 1.7 | 3.5 | 5.7 | 9.5 | 20 |

| 1000 | 6.5 | 1.1 | 2.3 | 3.8 | 6.3 | 13.3 | |

| 750 | 5 | 0.85 | 1.8 | 2.9 | 4.7 | 11 | |

| 160 | 1500 | 9 | 1.5 | 3.2 | 5.3 | 8 | 18 |

| 1000 | 6 | 1 | 2.1 | 3.5 | 5.3 | 12 | |

| 750 | 4.5 | 0.75 | 1.6 | 2.6 | 4 | 9 | |

注:配套电机功率:Nn≤容许功率÷2~2.5

3.连续工作型,减速器承载能力表

| 公称传动比i | 公称传速r/min | 规格 | |||||||

| 输入n1 | 输出n2 | 10 | 12 | 16 | 20 | 25 | |||

| 公称输入功率 P KW | |||||||||

| 22.4 | 1500 | 66 | 6.28 | 15.84 | 23.68 | 48.6 | 57.6 | ||

| 1000 | 44 | 4.48 | 11.2 | 16.30 | 33.5 | 39.7 | |||

| 750 | 33 | 3.10 | 7.9 | 11.8 | 24.3 | 28.8 | |||

| 25 | 1500 | 60 | 5.89 | 15.18 | 23.57 | 42.6 | 53.4 | ||

| 1000 | 40 | 4.20 | 10.8 | 16.25 | 29.35 | 36.8 | |||

| 750 | 30 | 2.90 | 7.5 | 11.75 | 21.3 | 26.7 | |||

| 28 | 1500 | 53.5 | 5.26 | 13.05 | 20.31 | 40.2 | 49.1 | ||

| 1000 | 35.5 | 3.75 | 9.30 | 14.00 | 27.7 | 33.86 | |||

| 750 | 26.5 | 2.50 | 6.50 | 10.1 | 20.1 | 24.5 | |||

| 31.5 | 1500 | 47.5 | 5.19 | 11.53 | 18.16 | 35.4 | 45 | ||

| 1000 | 31.5 | 3.70 | 8.23 | 12.5 | 24.4 | 31 | |||

| 750 | 23.5 | 2.50 | 5.75 | 9.1 | 17.5 | 22.5 | |||

| 35.5 | 1500 | 42 | 4. 45 | 10.18 | 16.99 | 30.6 | 42 | ||

| 1000 | 28 | 3.20 | 7.1 | 11.7 | 21 | 21.85 | |||

| 750 | 21 | 2.20 | 5.1 | 8.5 | 15.3 | 21 | |||

| 40 | 1500 | 37.5 | 4.04 | 8.88 | 15.10 | 24.6 | 36 | ||

| 1000 | 25 | 2.75 | 6.1 | 10.4 | 16.9 | 24.8 | |||

| 750 | 18.3 | 2.00 | 4.4 | 7.5 | 12.3 | 18 | |||

| 45 | 1500 | 33 | 3. 44 | 7.83 | 12.91 | 22.2 | 32.4 | ||

| 1000 | 22 | 2 .4 | 5.45 | 8.9 | 15.3 | 21.7 | |||

| 750 | 16.5 | 1.7 | 3.9 | 6.45 | 11 | 16.2 | |||

| 50 | 1500 | 30 | 3.21 | 7.00 | 12.06 | 21 | 30.6 | ||

| 1000 | 20 | 2.2 | 4.8 | 8.31 | 14.5 | 21.10 | |||

| 750 | 15 | 1.60 | 3.5 | 6.00 | 10.5 | 15.3 | |||

| 56 | 1500 | 26.5 | 2.71 | 6.01 | 10.43 | 16.2 | 27 | ||

| 1000 | 17.5 | 1.9 | 4.13 | 7.15 | 11.15 | 18.6 | |||

| 750 | 13 | 1.30 | 3.00 | 5.2 | 8 | 13.5 | |||

| 63 | 1500 | 23.5 | 2.43 | 5.32 | 9.56 | 15 | 25.3 | ||

| 1000 | 15.5 | 1.70 | 3.60 | 6.55 | 10.3 | 17.4 | |||

| 750 | 12 | 1.2 | 2.65 | 4.75 | 7.5 | 12.6 | |||

| 71 | 1500 | 21 | 2.24 | 4.95 | 8.08 | 13.2 | 21.8 | ||

| 1000 | 14 | 1.5 | 3.41 | 5.5 | 9.1 | 15 | |||

| 750 | 10.5 | 1.1 | 2.5 | 4 | 6.6 | 10.5 | |||

| 80 | 1500 | 18.5 | 1.85 | 4.13 | 6.85 | 10.2 | 21 | ||

| 1000 | 12.5 | 1.3 | 2.8 | 4.72 | 7 | 14.4 | |||

| 750 | 9 | 0.9 | 2.0 | 3.4 | 5.1 | 10 | |||

| 90 | 1500 | 16.5 | 1.70 | 3.89 | 5.74 | 9.6 | 16.3 | ||

| 1000 | 11 | 1.1 | 2.68 | 3.9 | 6.6 | 11.20 | |||

| 750 | 8 | 0.8 | 1.94 | 2.85 | 4.8 | 8.15 | |||

| 100 | 1500 | 15 | 1.49 | 3.13 | 5.24 | 7.8 | 15 | ||

| 1000 | 10 | 1 | 2.15 | 3.5 | 5.35 | 10 | |||

| 750 | 7.5 | 0.72 | 1.56 | 2.6 | 3.9 | 7.5 | |||

| 115 | 1500 | 13 | 1.40 | 3.09 | 5.05 | 7.2 | 15 | ||

| 1000 | 8.5 | 0.95 | 2.10 | 3.45 | 4.9 | ||||

| 750 | 6.5 | 0.70 | 1.5 | 2.50 | 3.6 | ||||

| 128 | 1500 | 11.5 | 0.16 | 2.58 | 4.28 | 6.36 | 13.8 | ||

| 1000 | 7.5 | 0.75 | 1.78 | 2.90 | 4.35 | 9.5 | |||

| 750 | 5.5 | 0.55 | 1.25 | 2.14 | 3.15 | 6.9 | |||

| 145 | 1500 | 10 | 1.06 | 2.43 | 3.59 | 5.7 | 12 | ||

| 1000 | 6.5 | 0.70 | 1.67 | 2.45 | 3.9 | 8.25 | |||

| 750 | 5 | 0.50 | 1.2 | 1.75 | 2.85 | 6 | |||

| 160 | 1500 | 9 | 0.93 | 1.96 | 3.25 | 4.87 | 10.8 | ||

| 1000 | 6 | 0.65 | 1.35 | 2.2 | 3.35 | 7.4 | |||

| 750 | 4.5 | 0.45 | 0.95 | 1.62 | 2.4 | 5.4 | |||

注:配套电机功率:Nn≤容许功率÷2~2.5

4.减速器输入轴至输出轴的中心矩

| 型号 | 10 | 12 | 16 | 20 | 25 |

| 中心矩a | 225 | 280 | 355 | 470 | 580 |

5.公称传动比

| 公称 | 22.4 | 25 | 28 | 31.5 | 35.5 | 40 | 45 | 50 | 56 |

| 63 | 71 | 80 | 90 | 100 | 114 | 128 | 145 | 160 |